GP49

Member

Offline Offline

Age: 15

Location: East of the sun and west of the moon, USA

Posts: 6,594

|

|

« on: December 11, 2010, 10:07:44 AM » |

|

After some time on the market and audiophile praise for its performance, the Kokomo thrust bearing retrofit kit for the Garrard 301 and 401 became controversial when some users reported that its ceramic thrust ball was wearing out the irreplaceable hardened steel spindles on their Garrards.

Now, without "admitting guilt," the maker of the Kokomo has introduced a new "Kokomo Kit Mk2." The description of the new kit makes no mention of a ceramic ball. Instead, it says: "The construction is changed to a hydraulic design, the means the spindle axis runs on a oil film and has no mechanical contact to the thrust plate. It´s a more high tech interpretation of the vintage 301 thrust plate. The Mk2 version sounds more “garrardy” and has more of the urban groove."

As usual, the maker of the Kokomo provides no illustration of the "business end" of the new Mk2 version.

The price of the new Kokomo Kit Mk2 is 83,19 Euro (not including VAT).

I have not seen this new version and have no experience with it, but welcome comments from anyone who has seen it or tried it.

|

|

|

|

« Last Edit: December 12, 2010, 01:16:33 AM by GP49 »

|

Logged

Logged

|

Gene

|

|

|

icefox a.k.a. Emmanuel

Member

Offline Offline

Location: Hong Kong

Posts: 246

|

|

« Reply #1 on: December 11, 2010, 01:42:17 PM » |

|

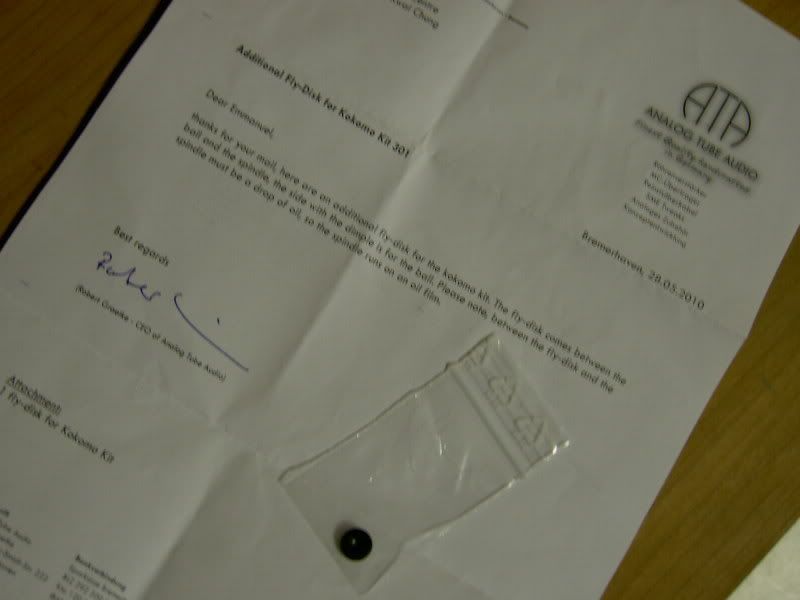

Hi Gene, I am also a customer of the KoKoMo kit base on the advocacy of David. This issue was once in my radar and I have had some proactive communication with ATA regarding this. You need to really push them to get feedback. Email is NOT the best way. If you don't mind, you can call them. I believe the "upgrade" is the provision of a nylon disc to interface between the ceramic ball and the bearing shaft. Below I would share some photos for your understanding. Cheers. E    |

|

|

|

|

Logged

Logged

|

|

|

|

wesley

Member

Offline Offline

Age: 67

Location: Los Angeles

Posts: 2,526

|

|

« Reply #2 on: December 11, 2010, 02:33:09 PM » |

|

shxt, that's what i need! icefox, did you complain and get that as a freebie fix for the original kit? or did they charge you?

|

|

|

|

|

Logged

Logged

|

regards,

wesley

Dial out the room and you'll enjoy your music more.

|

|

|

daiwok

Member

Offline Offline

Age: 54

Location: HONG KONG

Posts: 7,557

|

|

« Reply #3 on: December 11, 2010, 02:39:47 PM » |

|

shxt, that's what i need! icefox, did you complain and get that as a freebie fix for the original kit? or did they charge you?  he bxtched and got it for free ........ but he also bxtched for me and a couple of others and we got ziltch  |

|

|

|

|

Logged

Logged

|

David  Vinyl is BLACK MAGIC |

|

|

wesley

Member

Offline Offline

Age: 67

Location: Los Angeles

Posts: 2,526

|

|

« Reply #4 on: December 11, 2010, 02:42:57 PM » |

|

|

|

|

|

|

Logged

Logged

|

regards,

wesley

Dial out the room and you'll enjoy your music more.

|

|

|

daiwok

Member

Offline Offline

Age: 54

Location: HONG KONG

Posts: 7,557

|

|

« Reply #5 on: December 11, 2010, 02:47:02 PM » |

|

Make it a Typhoon Signal 10 for me please  |

|

|

|

|

Logged

Logged

|

David  Vinyl is BLACK MAGIC |

|

|

jaspert

Member

Offline Offline

Location: Melbourne, Australia

Posts: 1,184

tubey & horny

|

|

« Reply #6 on: December 11, 2010, 03:12:00 PM » |

|

I sent 2 emails and whinged... No reply and nothing in the mail.  Ice, Did you threaten to sue him in your email?  |

|

|

|

|

Logged

Logged

|

|

|

|

ebxb

Member

Offline Offline

Location: Canada

Posts: 82

I like popcorn.

|

|

« Reply #7 on: December 11, 2010, 05:42:46 PM » |

|

What is wrong with the original Garrard 301/401 bearing that needs to be retrofit with the Kokomo kit ?

|

|

|

|

|

Logged

Logged

|

Ed Vinyl, SET, Tannoy, Big Horn Speakers...and I'm crazy about TT. I think they are beautiful.  |

|

|

GP49

Member

Offline Offline

Age: 15

Location: East of the sun and west of the moon, USA

Posts: 6,594

|

|

« Reply #8 on: December 11, 2010, 06:08:10 PM » |

|

What is wrong with the original Garrard 301/401 bearing that needs to be retrofit with the Kokomo kit ?

The original 301 bearing was a flat thrust plate of bronze, with a precision, lapped, hardened flat on the bottom of the spindle running on it. It had grease lubrication (the famous and much sought-after "grease-bearing Garrard 301"). The later 301 and all 401, which used oil lubrication, had a dome-shaped bronze thrust plate with a smaller flat, against which ran the same type spindle. Over the years the dome-shaped bronze thrust plate would wear even flatter, increasing its surface area. Since Garrard stopped making the 401 in the 1970s, the supply of replacement thrust plates dried up. The original 301 grease-type thrust bearing virtually never wore out because of its larger flat surface area but had higher friction, even though it ran immersed in grease (it was actually more a very thick oil than a true grease). Whether the original 301 type or a worn sample of the late 301 or a 401, the flat vs. flat thrust bearing had higher friction than a ball-type thrust. Some say that's part of how the 301, especially the grease-bearing version, was SUPPOSED to work. Nevertheless, the aftermarket sprouted replacement thrust bearings with ball-type thrusts. Some are nylon inserts that hold a bronze ball; others are replacement thrust plates with a similar bronze ball. The Kokomo was a replacement thrust plate with a ceramic ball, claimed to be "soft ceramic" that was safe to use with the hardened steel Garrard spindle. But apparently that turned out not to be so; users discovered visible wear, with some saying that their irreplaceable Garrard spindles had a semi-spherical hole worn into them the exact size of the Kokomo ceramic ball. I thank "icefox" for the information on the revised design. It appears that the new Kokomo is a NYLON thrust with a precision flat on the top, against which the flat Garrard spindle runs. This would agree with the Kokomo manufacturer's description of the Kokomo Mk2 as a "more high tech interpretation of the vintage 301 thrust plate" which was a flat thrust and a flat spindle. |

|

|

|

|

Logged

Logged

|

Gene

|

|

|

ebxb

Member

Offline Offline

Location: Canada

Posts: 82

I like popcorn.

|

|

« Reply #9 on: December 11, 2010, 10:28:47 PM » |

|

Great Post and very detailed info.

For me, I wouldn't worry about the wear in the original bearing unless it is a BBC model or it is from a radio station or other commercial outlets. I believed most of the 301 or 401 were under use rather than over use. I will keep it original as long as possible or until there is a problem then I will look for a solution. I believed part of the so-called 301/401 sound signature are from its bearing construction.

|

|

|

|

« Last Edit: December 12, 2010, 08:12:46 PM by ebxb »

|

Logged

Logged

|

Ed Vinyl, SET, Tannoy, Big Horn Speakers...and I'm crazy about TT. I think they are beautiful.  |

|

|

icefox a.k.a. Emmanuel

Member

Offline Offline

Location: Hong Kong

Posts: 246

|

|

« Reply #10 on: December 12, 2010, 06:18:13 AM » |

|

I sent 2 emails and whinged... No reply and nothing in the mail.  Ice, Did you threaten to sue him in your email?  Hi Jas and Wesley, Quite honestly, I do not feel there is a huge issue with the ceramic ball touching the spindle directly. It does create a minute dimple on the spindle, I observed that when David came last time to change the ATA oil with some secret formula snake oil. There were two other friends in the occasion, we all feel quite surprised with the added musicality and coherency for just fiddling with the oil. I thought about the fly-disc afterward but never got the courage to put that in on my own. I need the helping hands from David and his snake oil. Regarding the freebie fly disc from Robert, I am indeed surprised with the snail mail he used to deliver that small fly-disc. I did write him back an email to thank him for the kind gesture. I also ask for 3 more discs (for David, kong and Jas). But they never turn-up. One of the reason why I got one may be because I highlight the fact that when I made my purchase (two sets, one for kong) it was the time that this dispute has just been disclosed. He talked about a revision in design and I reasoned that I should have received this. My suggestion for you is, make sure you have your proof purchase he send with the kit and a photos of the dimple in the spindle. Send him and email and then follow with a phone call to him making that is a serious matter for you and see if he would send you that fly-disc for free. Here is some photos showing the dimple in my 301's spindle after the commission of the KoKoMo kit mk1.   Good luck! E |

|

|

|

|

Logged

Logged

|

|

|

|

GP49

Member

Offline Offline

Age: 15

Location: East of the sun and west of the moon, USA

Posts: 6,594

|

|

« Reply #11 on: December 12, 2010, 06:33:51 AM » |

|

Beg to differ, but ANY dimpling on an irreplaceable part which is so key to the operation of a turntable is too much.

However to the credit of the Kokomo designer, the solution to the problem obviates any ill effects of the dimpling.

The wearing characteristics of the nylon may be a question, though by design it would be running in what amounts to an oil bath.

|

|

|

|

|

Logged

Logged

|

Gene

|

|

|

low pitch

Member

Offline Offline

Age: 73

Location: Perth Australia

Posts: 1,557

|

|

« Reply #12 on: December 12, 2010, 09:18:03 AM » |

|

I bought the Kokomo bearing and never fitted it due to the controversy. If the fix is just a nylon shim, and there is only point contact, wouldn't any flat disc suffice? Perhaps other materials eg brass / phosphor bronze might be better? It would be easy enough to cut from a piece of shimming. However if hte principle was to get a very hard small point contact then perhaps a ceramic disc or tungsten carbide might be possible to find? A ceramic ball on a nylon disc seems to negate teh whole thing.

martin

|

|

|

|

|

Logged

Logged

|

martin

"my hifi's waiting for a new tube..." Nina Simone 'turn me on'

|

|

|

wesley

Member

Offline Offline

Age: 67

Location: Los Angeles

Posts: 2,526

|

|

« Reply #13 on: December 12, 2010, 09:27:53 AM » |

|

if you think about the design of that disc, it might not be the correct answer. the kokomo bottom plate is already a convex hole, so there is a lot of surface contact. it you apply ANOTHER dimple on top, that means more surface area contact, which equates to more friction. i think the best way to fix the problem is to use a nylatron sheet (flat, so minimal contact) just like what is used in a lenco. once wear creates a dimple, then you just flip it or change to another pc. of nylatron. if i don't get a reply from atd (just emailed them this morning), then i will no longer be a customer. if anybody asks me if a kokomo kit is any good, i will just say, FORGET IT, IT'S A REALLY BAD DESIGN      .

|

|

|

|

« Last Edit: December 12, 2010, 09:32:20 AM by wesley »

|

Logged

Logged

|

regards,

wesley

Dial out the room and you'll enjoy your music more.

|

|

|

icefox a.k.a. Emmanuel

Member

Offline Offline

Location: Hong Kong

Posts: 246

|

|

« Reply #14 on: December 12, 2010, 10:14:48 AM » |

|

Wesley, I would certainly respect respect your choice. Do keep us post if you hear from Robert. This discussion gives me a bit of drive to try that fly-disc on. By the way, I am indeed not sure what exactly is the material used for the fly-disc. "Nylon" is what David suggested to me when I showed him the thing. BTW, I wonder if there is any German-literate Lenco forum member here could help posting an inquiry to Robert there. Robert seems to be more proactive on the the German Analogue Audio Association. Here is a thread that I saw Robert reference to the KoKoMo mk2. http://www.analog-forum.de/wbboard/index.php?page=Thread&threadID=37544&pageNo=2------- Hallo, die Druck bzw. Kräfteverhältnisse sind im Garrardlager konstant und somit reproduzierbar. Das Lager, Kugel und Oel wurde speziell auf diese Verhältnisse abgestimmt. Es ist aber ein Problem, besonders bei Garrard 401er, wenn der Achsspiegel durch den Verschleiss des originalen Drucklagers soweit beschädigt bzw. eingeschliffen ist, das die oberflächengehärtete Schicht abgetragen worden ist. In diesen Fällen passten die berechneten Verhältnisse nicht mehr und die Keramikkugel verdichtete minimal die Oberfläche der Lagerachse. Was durch einen kleinen wie hochglanzpolierten Punkt sichtbar wurde. Ein weiteres Szenario war und ist, wenn Künstler meinem, Sie müssen den Lagerspiegel der Achse polieren und haben dabei die oberflächengehärtete Schicht der Lagerachse wahrscheinlich ungewollt entfernt. Danach konnte man sich zwar in der Lagerachse spiegeln, aber die gehärtete Schicht ist abgetragen. Ich diesen Fällen gab es auch eine minimale Verdichtung, die durch einen winzigen polierten Punkt sichtbar wurde. Aussagen, wonach Garrards durch die Verwendung eines Kokomo-Lagers unwiderbringlich zerstört werden, sind dem Marketing-Denken von einzelen Leuten entsprungen, die das Thema sehr geschickt forciert haben. Eigentlich ist es genau anders herum, das originale Achslager beschädigt die Lagerachse. Auch wenn diese erneuert wird, bildet sich sehr schnell ein sichbarer Verschleiss an der Kalotte. Das grösste Problem dabei ist, das die abgetragenen Partikel den Verschleiss nochmals beschleunigen. Auch Konstruktionen mit einer Bronzekugel haben dieses Problem. In der Zwischenzeit gibt es eine MK2-Version des Kokomo-Lagers, bei der MK2-Version läuft der Achsspiegel mit Hilfe einer Flydisk auf einem hydraulischem Oelfilm. Somit hat die Lagerachse keinen direkten Kontakt und jegliche Beeinträchtigung der Achse ist ausgeschlossen. Der Ansatz zur MK2-Version kam daher, das ich einige Male die Kritik gehört habe, das der Garrard mit dem Kokomo Kit etwas von seinem ursprünglichen Charakter verlor. Ich habe mich vor ca. 1 Jahr dieser Kritik angenommen und eine Lösung entwickelt, die in der MK2-Version gründet. Mit dem Kokomo Kit MK2 ist wieder mehr von dem ursprünglichen Charakter des Garrards zu hören. MfG Robert Graetke Edit: Das Kokomo Kit MK1 ist auf die MK2-Version aufrüstbar! --------- |

|

|

|

|

Logged

Logged

|

|

|

|

|